Your Cart

- No products in the cart.

Subtotal:

$0.00

Other Popular Products

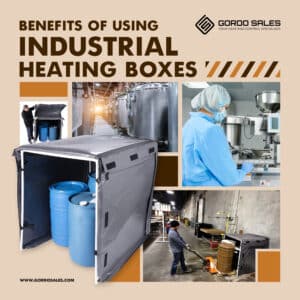

Industrial heat boxes have become indispensable in modern manufacturing processes, revolutionizing the way industries operate. These specialized enclosures offer precise temperature control and an array of benefits that optimize production, enhance quality control, and reduce costs. In this blog post, we will delve into the world of industrial heat boxes and uncover the numerous advantages they bring to manufacturing industries.

Industrial heat boxes play a vital role in improving process efficiency by providing controlled and consistent temperatures for various manufacturing stages. Whether it's drying, curing, annealing, or other heat-related processes, these enclosures ensure uniform heat distribution, reducing the likelihood of product defects or inconsistencies. With precise temperature control, manufacturers can achieve higher production rates, shorter cycle times, and improved overall process efficiency.

Maintaining stringent quality control is crucial for manufacturers to meet customer expectations and comply with industry standards. Industrial heat boxes offer a controlled environment where temperature-sensitive materials can be processed with precision. This level of control minimizes the risk of material degradation, warping, or structural defects, resulting in higher product quality and reliability. By consistently achieving desired temperature profiles, manufacturers can confidently produce products that meet or exceed quality standards.

Incorporating industrial heat boxes into manufacturing processes can lead to substantial cost savings. Firstly, precise temperature control reduces material waste by minimizing the occurrence of rejected or defective products. Additionally, optimized process efficiency and shorter cycle times translate into increased productivity and reduced labor costs. Moreover, some modern heat boxes are designed with energy-efficient features that minimize power consumption, further contributing to cost reduction and sustainability goals.

Industrial heat boxes are highly versatile and can be tailored to suit specific manufacturing requirements across a wide range of industries. These enclosures are available in various sizes, configurations, and temperature ranges, accommodating diverse applications. Whether it's electronics, food and beverage, pharmaceuticals, or other sectors, heat boxes can be customized to cater to the unique needs of each industry, providing adaptable solutions for temperature-sensitive processes.

Manufacturing processes involving heat can carry inherent risks, including fire hazards and worker safety concerns. Industrial heat boxes are designed with safety in mind, incorporating features such as fireproofing measures, insulation, and advanced ventilation systems. By confining the heat within controlled enclosures, these solutions mitigate the risk of accidents and create a safer working environment for employees. Additionally, adherence to regulatory standards and compliance requirements is easier to achieve with the implementation of these purpose-built enclosures.

Industrial heat boxes have revolutionized manufacturing processes, offering precise temperature control, enhanced efficiency, improved quality control, and significant cost savings. With their versatility, adaptability, and focus on safety, these enclosures have become essential tools across a wide range of industries. By harnessing the power of industrial heat boxes, manufacturers can elevate their production capabilities, deliver superior products, and stay ahead in today's competitive marketplace.