Your Cart

- No products in the cart.

Subtotal:

$0.00

Other Popular Products

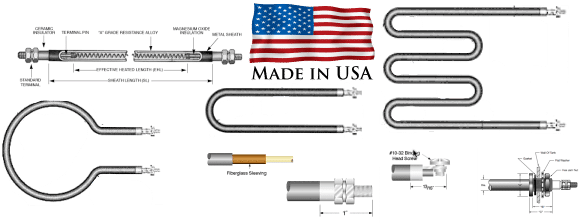

Tubular heating elements are versatile and transfer heat exceptionally well by conduction, convection, or radiant heating to heat liquids, air, gases, and surfaces. Round, triangular, flat press, and formed bends are made to customer requirements. A multitude of sheath materials are available. More than 20 optimal terminations and many stocked accessories are available. Can be furnished as UL-listed and CSA-certified. VDE and CE certification also available.

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration. The basic design consists of a helical coil of nickel-chromium resistance wire precisely centered in a metal sheath. This coil is surrounded by magnesium oxide powder which is vibration loaded to insure even density throughout the length of the heater. This entire assembly is then reduced to the finished diameter, compacting the MgO and "freezing" the coil in the center of the heater. The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial and scientific applications.

Read more...

Click here for typical bend formationsThe following are the most common tubular element sheath materials.

Call or email us for application assistance and pricing (801) 544-4236.