Description

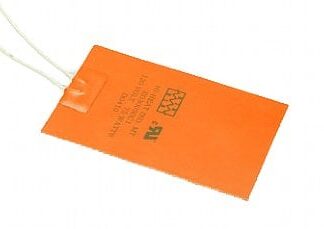

120V 50W 1"" w x 10"" with 8"" standard silicone rubber leads

- Volts: 120V

- Watts: 50W

- Watts Per Square Inch: 5

- Width: 1""

- Length: 10""

- PSA- The maximum service temperature of this high temp silicone pressure sensitive adhesive (PSA) is 500℉ (260℃). This adhesive is used on silicone rubber heaters. Bond strength is improved if a dwell time of 12 hours is observed before heater operation.

- Heaters can be fabricated with thermostats, thermal fuses, temperature sensors, thermocouples and resistance temperature detectors (RTD) as an integral part of the heater, call us.

- Fasteners for heating applications on cylindrical parts or where the installation is temporary, eyelets with springs or snap fasteners are used to mount heaters. Spring fasteners allow for variations in circumference while providing close contact with the part to be heated. Many types of fasteners used for canvas or leather can be built into the sheath of the heaters, call us.

Silicone rubber heaters provide dependable performance under rigorous conditions. Ambient temperatures down to -80F and up to 500F do not diminish performance.

The excellent dielectric properties of silicone rubber and the strength of fiberglass combine to produce a unique heater. First, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine, producing a strong, flexible heating element. Electronically-controlled precision winding equipment ensures consistency.

Circuits are then hand-wound on permanent tooling providing repeatability of resistance and pattern. Parallel circuits are utilized where possible, permitting continued operation should a single circuit be damaged.

When the heating element is positioned, a second layer of silicone rubber is laid over the wire. The layers are then vulcanized to permanently position the circuits.

Using these versatile and flexible heaters, the ability to apply heat exactly where required is limited only by imagination and a maximum continuous operating temperature of about 200C (392F).

We can have manufactured almost any size or shape for your custom application, lead time us usually 4-5 weeks, call us for more information (801) 544-4236.