Description

SPS Series - For Commercial/Industrial Use Only

The Economical Alternative for Hard-to-Heat Spaces

Whether you need to heat your warehouse, garage, or other hard-to-heat spaces, the SunStar SPS/U Series infrared heaters provide both the field efficiency of radiant heat and the installation flexibility you need…and all at a comfortable price.

- Push Through System

- 8 different Btu sizes and more than 60 different configurations to custom design your infrared heating system

- CSA design certified

- Available in natural and propane gas

- Optional elbows and corner reflectors

- Optional decorative grille

- Sidewall or through the roof venting

- Vented or indirect vented operation

- Includes 36″ stainless steel gas connector

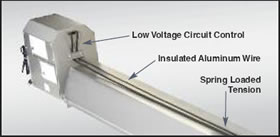

Introducing TISS™ Tube Integrity Safety Shut-Off System

SunStar’s patent pending innovative safety feature for positive pressure radiant tube heaters is called the “Tube Integrity Safety System” (TISS™).

SunStar’s patent pending innovative safety feature for positive pressure radiant tube heaters is called the “Tube Integrity Safety System” (TISS™).

In the unlikely event of a tube failure, TISS™ has been designed to automatically shut off the heater. The revolutionary TISS™ uses a simple principle to place an electrically insulated aluminum wire in tension above the reflector. Low voltage is then continuously passed along the wire in line with the gas control circuit. If heat levels increase due to heat exchanger failure, the wire melts and the safety circuit is broken, breaking the 24 volt circuit and shutting down the heater.

You may never know it is there, but it provides peace of mind.

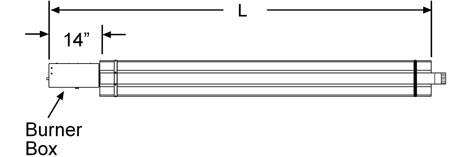

SPS Dimensions

| Model | Total Tube Length | Overall Dimensions "L" (FT) |

|---|---|---|

| SPS (40) | 10' | 17' |

| SPS (40, 50, 75) | 20' | 22' |

| SPS (50, 75, 100, 125) | 30' | 32' |

| SPS (100,125, 150, 175) | 40' | 42' |

| SPS (125, 150, 175, 200) | 50' | 52' |

| SPS (150, 175, 200) | 60' | 62' |

| SPS (175, 200) | 70' | 72' |

| Model | BTU/HR Input | Total Emitter Tube Length | ||||||

|---|---|---|---|---|---|---|---|---|

| 10 FT. | 20 FT. | 30 FT. | 40 FT. | 50 FT. | 60 FT. | 70 FT. | ||

| SPS 40 | 40,000 | ✓ | ✓ | |||||

| SPS 50 | 50,000 | ✓ | ✓ | ✓ | ||||

| SPS 75 | 75,000 | ✓ | ✓ | ✓ | ||||

| SPS 100 | 100,000 | ✓ | ✓ | |||||

| SPS 125 | 125,000 | ✓ | ✓ | ✓ | ✓ | |||

| SPS 150 | 150,000 | ✓ | ✓ | ✓ | ||||

| SPS 175 | 175,000 | ✓ | ✓ | ✓ | ||||

| SPS 200 | 200,000 | ✓ | ✓ | ✓ | ||||

*Model number is based on Btu/hr input (e.g., 100,000 Btu/hr), total emitter length (e.g., 40 feet) and control suffix for gas type (eg. natural gas-single stage-N5 or two stage-N7). For example, the model number for a straight tube single stage heater would be SPS100-40-N5 and for a U-tube heater would be SPU100-40-N5.

Tough Guy Option: All aluminized steel radiant tubes

For Tough Guy option the model number would be SPS100-40-TG-N5. Note: for Carwashes, Dairy Barns, Greenhouses, Swimming Pools, Waste Water Treatment Plants, and other high humidity / corrosive environments, Tough Guy with all aluminized tubes is recommended.

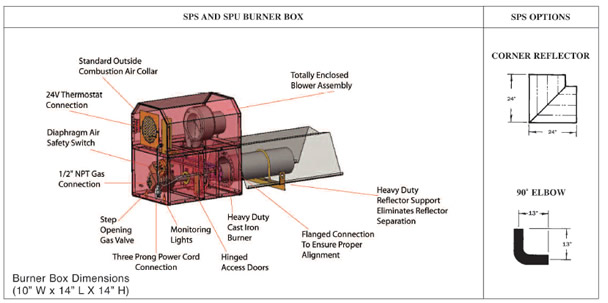

SPS Supply Requirements

| Gas Type | Burner Pressure | Supply Pressure | Voltage | Amps | Ignition Type | |

|---|---|---|---|---|---|---|

| MIN | MAX | |||||

| Natural | 3.5" W.C. | 5" W.C. | 14" W.C. | 120 VAC 60 Hz | 2.4 | Direct Spark |

| Propane | 10" W.C. | 11" W.C. | 14" W.C. | 120 VAC 60 Hz | 2.4 | Direct Spark |

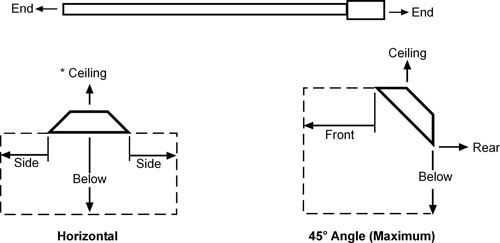

SPS Minimum Mounting Heights

| Model | Height at Horizontal | Height at 45° Angle |

|---|---|---|

| SPS 40 | 10' | 9' |

| SPS 50 | 11' | 10' |

| SPS 75 | 13' | 12' |

| SPS 100 | 14' | 13' |

| SPS 125 | 14' | 13' |

| SPS 150 | 15' | 14' |

| SPS 175 | 16' | 15' |

| SPS 200 | 18' | 16' |

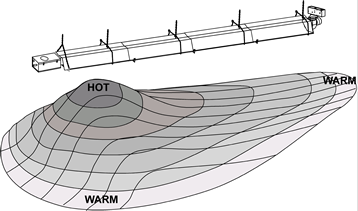

NOTES: Since straight tubes are always hotter at the burner end than at the exhaust end, always observe the minimum recommended mounting heights shown on the specification sheet for greatest human comfort. Use SPU series instead of SPS series for spot heating applications.

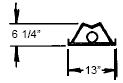

SPS Clearances to Combustibles

| Model | Side | Ceiling* | Below | End | (45°) Front | (45°) Rear |

|---|---|---|---|---|---|---|

| SPS 40 | 22" | 6" | 52" | 15" | 40" | 12" |

| SPS 50 | 22" | 6" | 56" | 15" | 48" | 12" |

| SPS 75 | 22" | 6" | 60" | 15" | 52" | 12" |

| SPS 100 | 28" | 6" | 70" ** | 15" | 58" | 12" |

| SPS 125 | 28" | 6" | 76" ** | 20" | 66" | 12" |

| SPS 150 | 34" | 6" | 81" ** | 20" | 70" | 12" |

| SPS 175 | 38" | 6" | 86" ** | 20" | 75" | 12" |

| SPS 200 | 42" | 6" | 93" ** | 20" | 80" | 12" |

* When used indirect vented, minimum clearance for Ceiling must be: 12″ for SPS 40-75, and 18″ for SPS 100-200. If optional corner and u-bend reflectors are not used, the clearance must be 18″.

** Maximum clearance below reduces by 50% once you are 25ft. downstream from the burner box.